|

| Automated Detection, Classification and Marking of Surface Deformations | |||||

| Participants Arjun Yogeswaran M.A.Sc. student 2008-2011 Valentin Borsu M.A.Sc. student 2008-2010 Collaborators Neptec Design Group Precarn Automotive Parts Manufacturers Association Honda Canada |

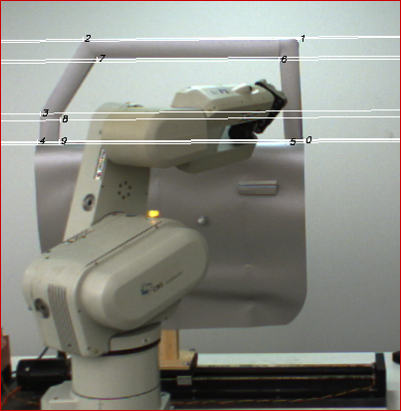

Quality control in the manufacturing industry has traditionally been performed manually. However, with advances in sensor technologies

and robotics, automated inspection is quickly penetrating this area of operation, leading to more accurate, efficient, safe and cost effective solutions.

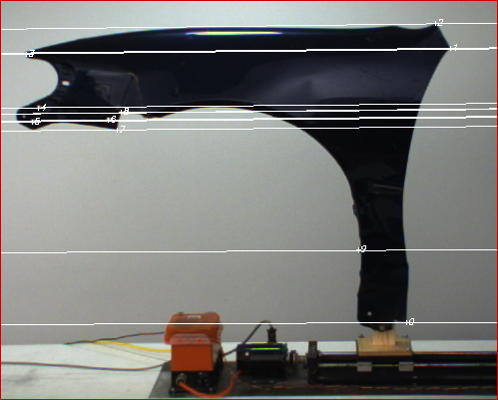

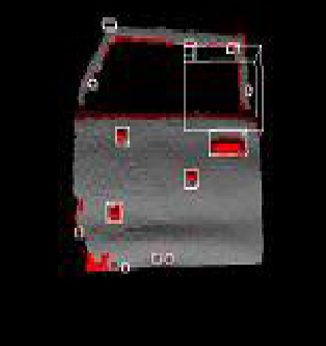

In the automotive industry, high standards of quality are imposed on the finish of body parts. As such, identifying tiny deformations such as dings

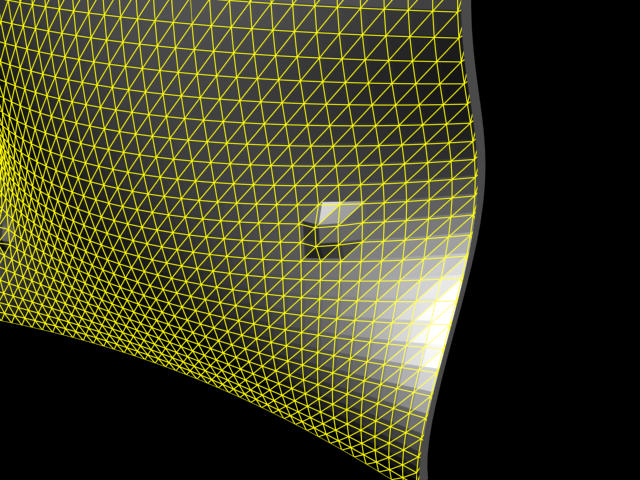

and dents on body panels, and marking them automatically on a moving assembly line, is essential. This can be achieved using high-accuracy

3D imaging, advanced shape deformation detection algorithms, and robotic marking approaches that are accurately calibrated with the assembly line. This research develops innovative feature extraction and classification algorithms that operate from 3D surface scan measurements and that can handle defects of variable size, scale and density, while accomodating the aesthetic curves and features that characterize automative body surfaces. Automated marking of the exact locations where deformations appear over an automotive body panel while it moves on an assembly line is also integrated in the solution. Pose and motion of the body panel on the assembly line are accurately estimated, while not requiring any CAD model of the body assembly, and therefore maximizing the flexibility of the solution. The project is conducted in close collaboration with industry to address their actual needs and the proposed automated inspection and marking station is experimentally validated on real body panels with surface deformations.

|

Related Publications

|

© SMART Research Group, 2012